Subsection 7.3.12 DC Heater

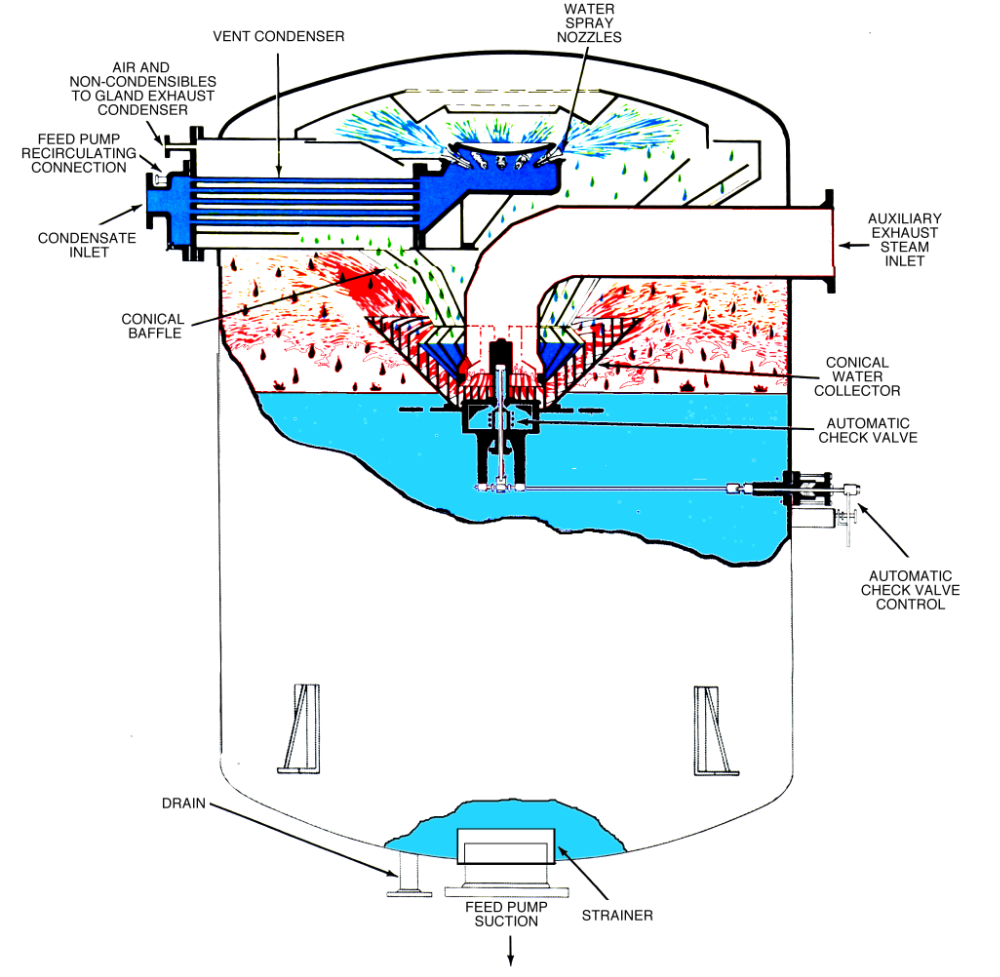

The first stage heater is followed by the second stage heater, which is usually referred to as the DC Heater. The DC Heater is the point in the steam cycle where condensate becomes feed water.

The DC heater provides a second stage of regenerative feed heating, which is accomplished by mixing low pressure steam directly with the condensate. In other words, the heat exchange occurs by direct contact, hence the name. The DC Heater is also sometimes called deaerating feed tank, the DFT, the deaerator, as well as the second stage heater. All these names refer to the same piece of equipment.

The DC Heater serves three important functions in the steam cycle:

Heat.

The first function of the DC Heater is to heat the feedwater prior to returning it to the boiler. Thermodynamically, it is known as the regenerative second stage heater. Using the exhaust steam from steam powered auxiliaries to heat the DC Heater increases the overall plant efficiency and saves fuel.

Deaerate.

The second function of the DC Heater is to remove dissolved gases (oxygen and free carbon dioxide) from the condensate and make-up water used for boiler feed. Removal of oxygen and free carbon dioxide protects piping and pumps, as well as boilers and condensate return lines from these corrosive gases.

Store.

Finally the DC Heater acts as a storage location for feedwater. It acts as a surge tank for the system, allowing fluctuations in the amount of water contained in the cycle to occur without upsetting the feed pump and feedwater regulators.