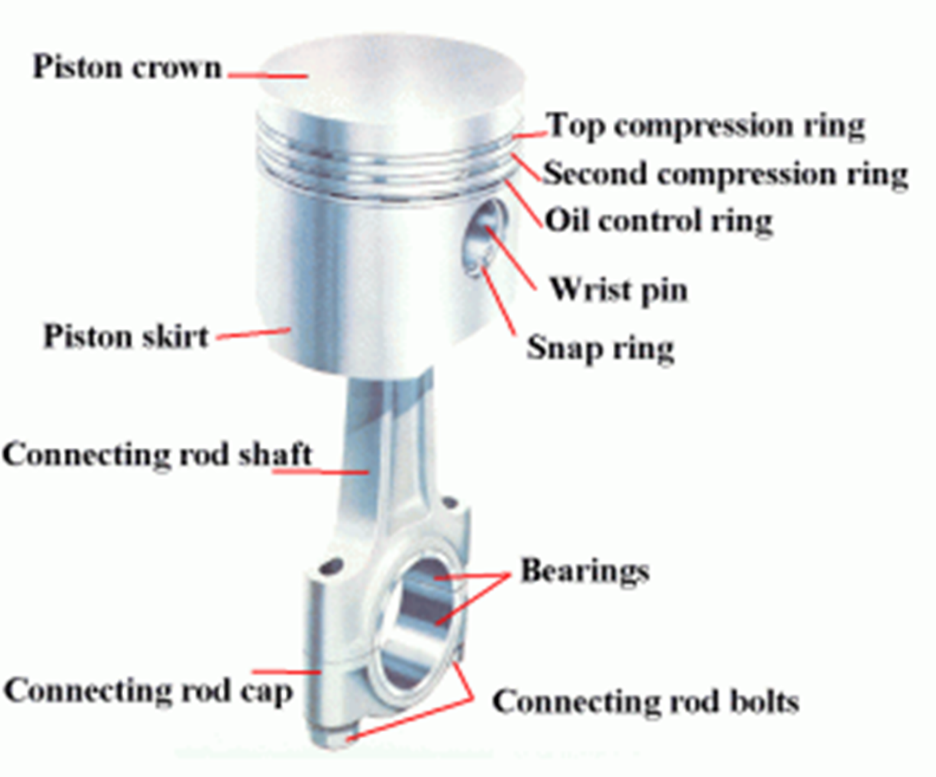

Subsection 6.4.4 Piston and Piston Rings

The piston transforms the energy of the expanding gases into mechanical energy. The piston rides in the cylinder liner or sleeve and the pressure of the combustion gases act on the piston head to move the piston dowm. This motion is transmitted through the connecting rod to rotate the crankshaft. Pistons are commonly made of aluminum or cast iron alloys.

To prevent the combustion gases from bypassing the piston and to keep friction to a minimum, each piston has between 2 to 5 metal piston rings around it. These rings provide a seal between the piston and the cylinder wall and also reduce friction by minimizing the contact area between the piston and the cylinder wall and distributing lubricating oil. The rings are usually made of cast iron and coated with chrome or molybdenum.

Each ring performs a distinct function. The uppermost rings acts primarily as the pressure seal and are known as compression rings. The intermediate rings acts as wiper rings to remove and control the amount of oil film on the cylinder walls. The bottom rings are oiler rings and they ensure that the lubricating oil is evenly deposited on the cylinder walls.