Subsubsection Soundings

In the maritime community the process of measuring the depth of water below the vessel or the content level of tanks, is called sounding. In other industries, this process may be called tank gauging.

Sounding the ship’s tanks (fuel oil, lube oil, fresh water, cargo, bilges, etc) provides a measure of the volume the contents. Regular sounding and monitoring tank levels is required for the safe operation of the vessel many reasons, including:

- To ensure that there is enough fuel and water to safely complete the voyage and not leave the ship stranded.

- To avoid spills caused by overfilling tanks.

- To maintain the ship’s stability, which depends on the location and weight of the tank contents, and is degraded by the free surface of partially filled tanks.

- To determine when to refill service tanks as the contents are consumed.

- To plan for bunkering and taking on cargo.

- To detect leaks or loss of content from the tank.

Manual Sounding.

Many of the ship’s tanks are sounded manually.

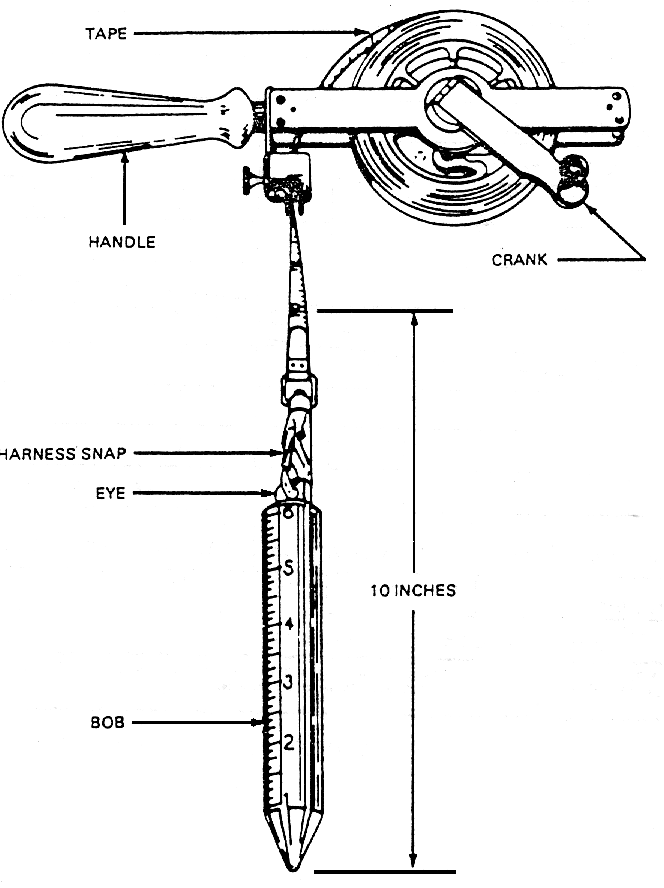

All important tanks on ships are provided with sounding tubes, tubes which extend from the top of the tank to the bottom. A crew member can lower a flexible sounding tape down the tube to measure the level in the tank manually. Sounding tapes are normally made of brass and steel, and consist of a spool, a flexible tape measure, and a weighted bob attached at the end of the tape.

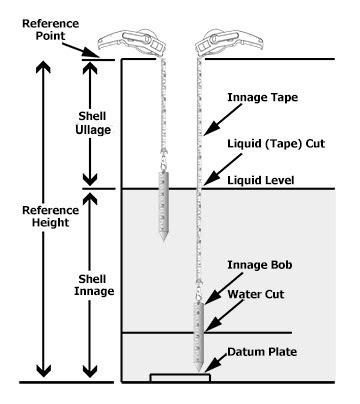

The sounding tape can be used in either of two ways. An innage is a measurement from the top of the liquid to the bottom of the sounding tube, while an ullage is a measurement from the top of the sounding tube to the surface of the liquid. Either method will reveal how full or empty the tank is.

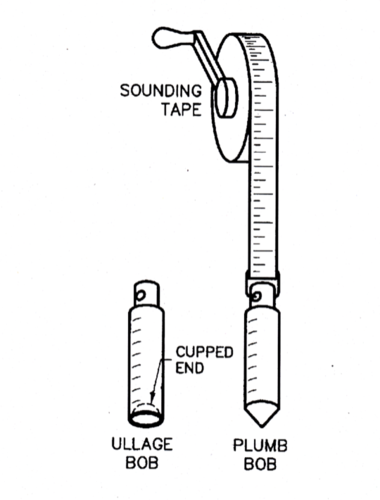

An ullage bob has a cupped end which will produce a "popping" sound that can be heard from the top of the sounding tube when it is bounced on the liquid surface. When taking an ullage, try to locate the top surface without dropping the tape too deep.

An innage bob has a pointed end, and is used by dropping the tape to the bottom of the tank and noting where the liquid (or cut) line appears, much like using a dipstick in your car. The cut line is easier to detect in oil tanks than in water tanks. The innage bob has a ruler marked on it, which can be used to measure the depth of any water at the bottom of oil tanks by coating the bob with chalk, which will change color if it enters water.

When you finish using a sounding tape on an oil tank, you must wipe the oil off the tape before putting it away. Ullage soundings don’t leave as much oil on the tape, so they are often preferred for oil tanks.

Although knowing the tank level is sufficient for many purposes, the actual volume of the contents in gallons or tons can be looked up in the Tank Tables. These tables, which depend on the specific shape of each tank, relate tank level to volume. For highly accurate results, the list and trim of the ship and the temperature of the contents (which affects its density) must be taken into account.

Level Meaurement.

Many other methods of measuring liquid levels are available. Some found ship include:

Gage glasses, also known as sight glasses, provide a transparent window into the tank, allowing for direct visual observation of the liquid level inside. The glass tube on a coffee urn is an example.

Mechanical level gauges use a float attached to a pointer through a pulley system. As the liquid level changes, the float moves, causing the pointer to indicate the new level.

Differential Pressure level gauges measure the pressure difference between two points in the tank to determine the liquid level.

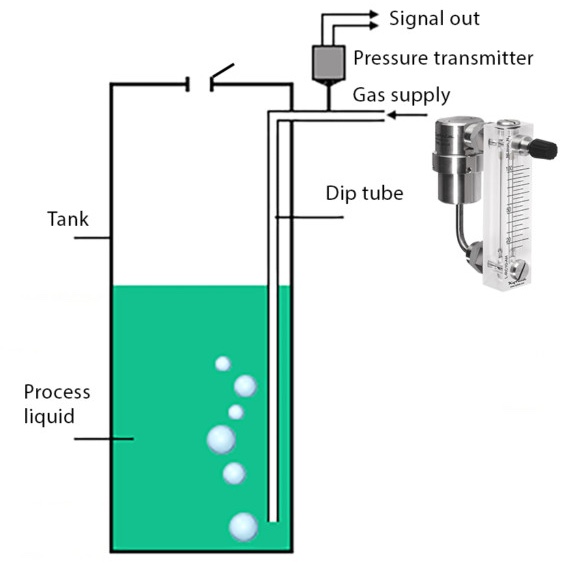

Pneumercator or bubbler gages operate based on hydrostatic pressure measurement. A bubbler system introduces a small amount of air at a near constant flow rate into the liquid through a dip tube to the bottom of the liquid. The pressure required to overcome the liquid head is measured and translated into a liquid level reading.

Ultrasonic level gauges function similarly to echo sounders. They emit ultrasonic waves from the gauge, which travel through the liquid and reflect off the surface. The sensor detects the time it takes for the echo to return, and a microprocessor then calculates the distance between the sensor and the liquid surface. These gauges are known for their accurate, non-contact measurement capabilities.