Subsubsection Compression Connections

In some systems, mechanically strong, leak tight connections can by compressing the pipe or tube in a compression or flare fitting.

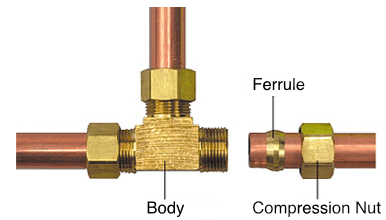

Compression fittings are made up of three basic elements: the compression nut , the ferrule , and the body. The tubing is slipped through the nut and the ferrule and then inserted into the end of the body. By tightening the nut/screw the ferrule is forced into the fitting body. As the ferrule moves axially into the fitting body, the body’s angled shape compresses the end of the ferrule onto the outer diameter of the tubing. It is this radial compression that creates a leak tight seal between the fitting, ferrule, and tubing, and gives the compression fitting its name.

Flare fittings consist of a body with a flared or coned end. Special flaring tools are used to create a matching flare on the pipe. The flare nut compresses the flare into the fitting body and creates the seal. Flare fittings can handle higher pressures and a wider range of operating parameters than standard compression fittings.

Compression connections are quick and require little skill to make, but they cannot withstand very high pressures. Also, there are only a few materials that are suitably compressible (ex. copper, brass, plastic) to use this method.