Subsection 5.2.4 Plug-type Valves

Plug-type valves have a rotating element with a hole drilled or cast through it. When the hole lines up with the matching passages in the valve body, fluid can flow through the valve. Variations of plug valves are pet cocks, cylinder valves or ball valves.

Plug Valves.

Plug valves, Figure 5.2.9, have a through-ported cylindrical or tapered plug which can rotate in a close-fitting body. Alignment of the ports (holes) in the plug with those in the body permit fluid flow.

Operation of a plug valve requires rotating the handle or lever on the plug stem 90 degrees. Normally the plug valves (for the most common type with two pipe connections 180 degrees apart) position (open or closed) can be determined by looking at the operating lever. When the lever is parallel to the piping system, the valve is open. When the lever is perpendicular to the piping system, the valve is closed.

Plugs valves have limited throttling ability and should be used like gate valves, either fully open or closed.

Plug valves may be built with multiple openings in the plug and multiple ports in the valve body. These designs allow a variety of fluid flow directions through the plug valve by proper positioning of the operating lever. Pointers attached to the plug stem or operating lever are sometimes used to indicate direction of flow.

When a plug valve is described as “three-way, two-port” it means the valve body has three openings to pipe connections on the outside of the body. Two port means the plug has two openings in it that fluid flows in and out through.

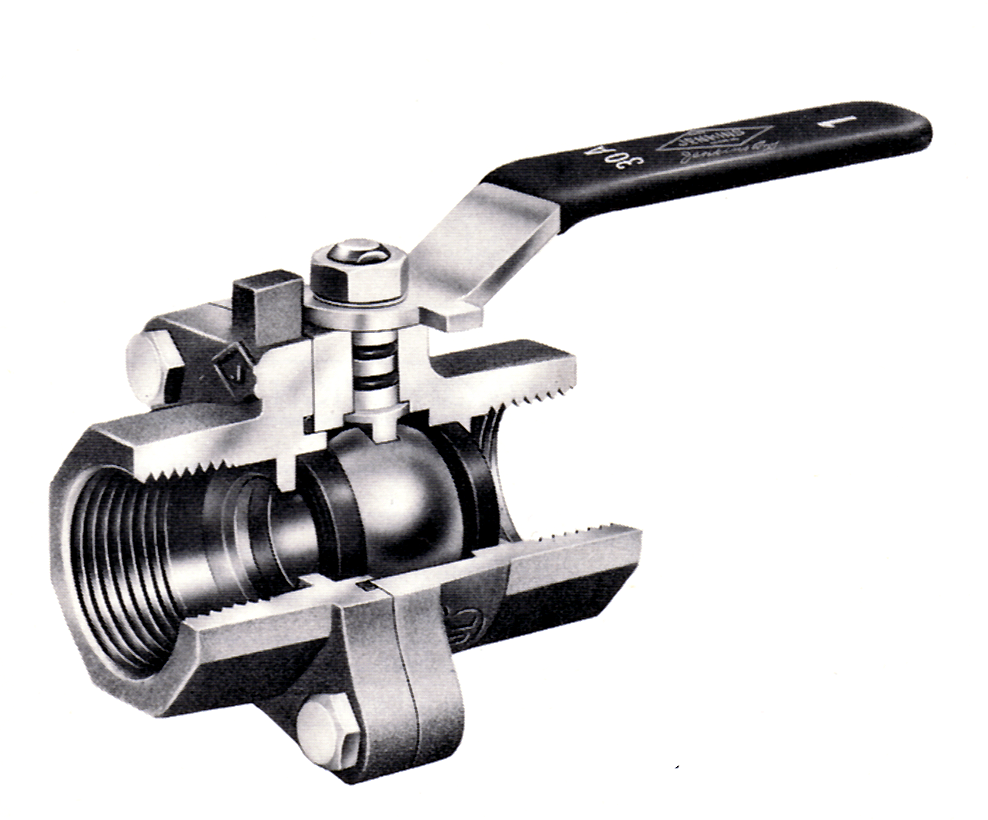

Ball Valves.

A ball valve, Figure 5.2.10, is similar to a plug valve except that a spherical rather than cylindrical plug is used. The ball has a hole or port bored through it and is made tight to the two openings in the body by plastic or synthetic rubber seat seal rings. These plastic or synthetic seat rings limit most ball valves to fluid temperatures of 350° or less. When the ball is rotated to the closed position, the fluid pressure pushes the ball tightly against the outlet seat ring insuring tight closure.

Ball valves are compact, self-sealing, non-sticking, require little effort to rotate the valve stem and they provide smooth fluid flow. Since the port in the ball is normally the same I.D. as the piping, the ball valve offers little resistance to flow and low pressure drop.