Subsection 1.3.1 Head Protection

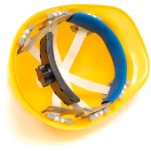

Head injuries are caused by falling or flying objects, or by bumping your head against a fixed object. Head protection, in the form of protective hats, must do two things – resist penetration and absorb the shock of the blow. This is accomplished by making the shell of the hat of a material hard enough to resist the blow, and by utilizing a shock-absorbing lining composed of headband and crown straps to keep the shell away from the wearer’s skull. Protective hats are also used to protect against electric shock.

There are several types of hard hats available, each designed for specific purposes and levels of protection.

Class G (General) hard hats and caps are intended for general service and they provide protection against impact hazards and a limited protection against electrical shock (up to 2,200 V). They are used in industries such as construction, manufacturing, mining, and shipbuilding. This is the most suitable hard hat for shipboard use.

Class E (Electrical) hard hats are utility service hats which are designed to protect the wearer’s head from impact and penetration by falling or flying objects and from high-voltage shock (up to 20,000 V). They are used extensively by electrical workers.

Class C (Conductive) hard hats or caps, are designed to be light and comfortable while protecting against impact hazards, but they do not provide any protection against contact with electrical conductors. Class C hats often have a front brim to protect the face from sun, reduce glare, and help shed rain. They are used on occasions where there is a possibility of falling objects or bumping the head, but no risk of electrical shock.

Bump caps are less obtrusive than hard hats and are designed to provide comfortable, lightweight but they have limited protection against minor head bumps, knocks, and scrapes. They in environments where there is a risk of hitting the head on objects such as low ceilings, beams, or equipment. They are not meant a substitute for a hard hat because they do not afford protection from high electrical shock, high impact forces, or penetration by falling objects, and they are not OSHA approved, so they can not be used in situations where a hard hat is required.

Before using a hard hat you should inspect it for signs of damage or abuse of the helmet or any of its parts. A damaged helmet reduces the margin of safety the hat was designed to supply, and should be replaced immediately.

Correct adjustment and fit of the your hard hat is required for maximum safety. The internal cradle of the headband and sweatband forms a suspension system which keeps the helmet away from the head and cushions against impact. The headband must be adjusted to the right size in order to provide sufficient clearance between the shell and the headband.