Subsection 2.5.4 Torque Measurement

Several tools are available for measuring torque. Some which you may encounter are:

Torque Wrench.

A torque wrench is a precision tool commonly used to apply a specific amount of torque to fasteners such as nuts and bolts. A torque wrench has a calibrated scale or a digital display that allows the user to set and control the applied torque accurately.

Torque wrenches are used to apply precise amounts of torque to fasteners, ensuring they are neither too loose nor too tight. Over-tightening can strip threads or break fasteners, while under-tightening can lead to parts coming loose or failing to function properly. Manufacturers specify torque requirements for their products, and adhering to these specifications is often necessary to prevent damage and maintain warranties.

Torque Sensors.

Torque Transducers, also commonly known as torque sensors, torque cells, or, torque gauges are devices that measure the torque applied to a stationary object or produced by a rotating system. These devices convert a torque measurement (reaction, dynamic or rotary) into an electrical signal that can be integrated into control systems or used as standalone devices to provide real-time torque measurements.

Rotary torque transducers measure the torque on rotating parts such as motors, crankshafts, and gearboxes.

Static torque transducers measure reaction torque without requiring the shaft to rotate. They are used where the torque of stationary objects needs to be measured.

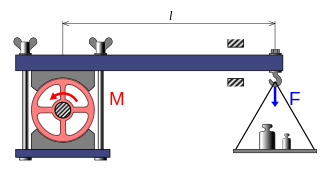

Dynamometers.

A Prony brake is a friction brake and torque-measuring system that was invented by French mathematician and engineer Gaspard de Prony in 1821. The term "brake horsepower" is one measurement of power derived from this method of measuring torque. (Power is calculated by multiplying torque by rotational speed.) It is also known as an absorption dynamometer.