Subsection 2.8.2 Temperature Measuring Instruments

Various instruments are used to measure temperature in different applications. The choice of temperature measurement instrument depends on factors such as the required accuracy, temperature range, and the specific application or industry. Different instruments are suitable for different temperature ranges and environments.

Here are some common instruments used to measure temperature:

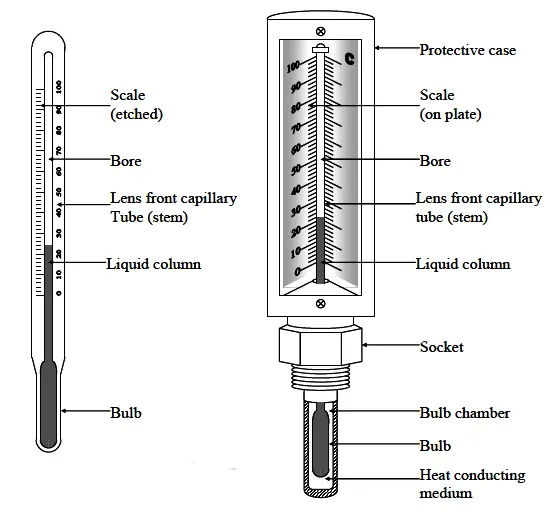

Liquid in Glass Thermometers are the most common instruments for measuring temperature. The basic principle involves the expansion or contraction of a temperature-sensitive substance in response to temperature changes. This type of thermometer consists of a liquid (usually mercury or colored alcohol) sealed in a glass tube. The liquid expands or contracts with temperature changes, and the temperature is read from a scale etched on the thermometer.

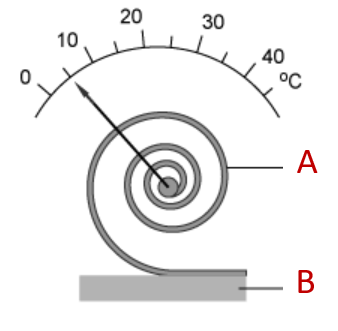

Bimetallic temperature sensors use the differential expansion of two metals to detect temperature changes. These are often used in thermostats and mechanical temperature gauges.

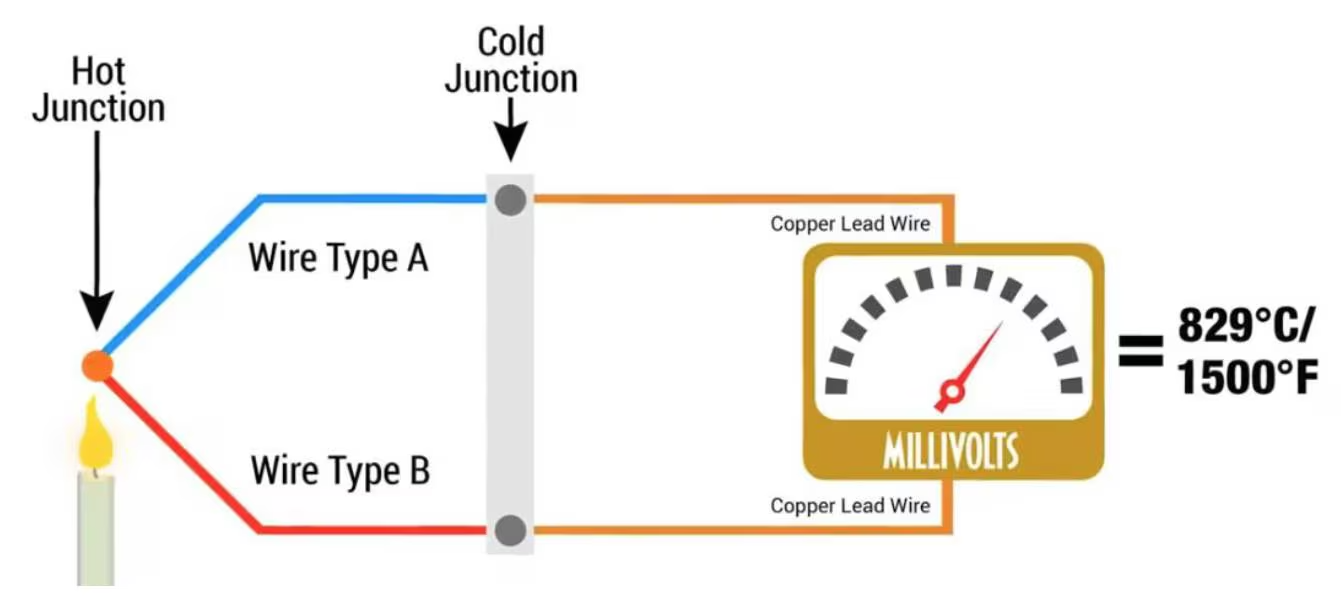

A thermocouple is a device which measures temperature using the Seebeck effect. In 1821, Thomas Seebeck discovered that a voltage will be generated in a wire loop made from two dissimilar conductors when two junctions are maintained at different temperatures. The Seebeck effect is used to measure temperature with great sensitivity and accuracy .

A thermocouple consists of two metal wires made of different materials, joined at one end to form a junction. The junction, called the hot junction, is placed where the high temperature is to be determined, while the other ends, called the cold junction, are maintained at a lower, stable temperature. The voltage difference between the wires at the cold junction is used to determine the temperature at the hot junction.

Thermocouples are designated by letters and colors indicating the specific pairs of metals used. The most common thermocouple types are J (black), K (yellow) and T (blue). The choice of a thermocouple is based on the required temperature range and accuracy.

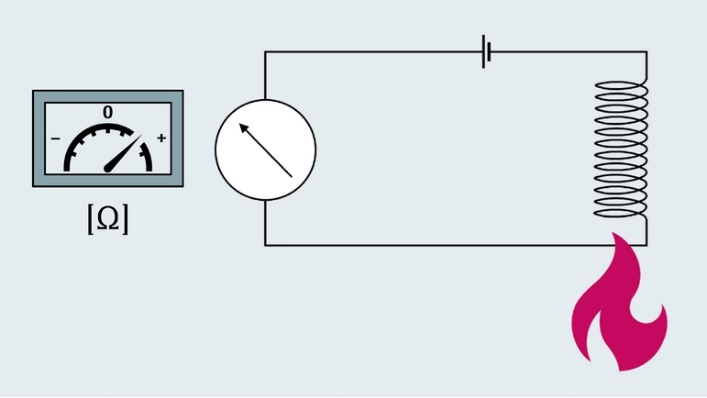

A Resistance Temperature Detector or RTD is a device that determines the temperature of an object by measuring the electrical resistance of a sensing element, The sensors resistance changes linearly as a function of temperature, increasing as the temperature rises and decreasing when the sensor cools.

Most RTDs are either wire wound or thin film types Wire wound RTDs use a fine platinum wire wrapped around a glass or ceramic core, while thin film RTDs use a base ceramic element with a platinum track deposited on it. In either case, the sensing element normally housed in a protective probe to protect them from the environment they are immersed in and to make them more robust.

While thermocouples and RTDs both measure temperature, there are several differences between the two methods, such as:

- Thermocouples are usually smaller than RTDs, making them easier to use.

- Thermocouples (-200 to 2000°C) offer a wider range of temperature operation than RTDs (-200 to 600° C). This means that thermocouples are suitable for more applications.

- Thermocouples offer a response time between 0.1 and 10s which is faster than the response time of RTD sensors.

- RTDs can self-heat while this issue is negligible with the thermocouples.

- Thermocouplesare more sensitive than RTD temperature sensors. This is so because these react faster than RTDs with the variation in temperature.

- For thermocouples, the graph between resistance and temperature is not linear, while an RTD is linear.

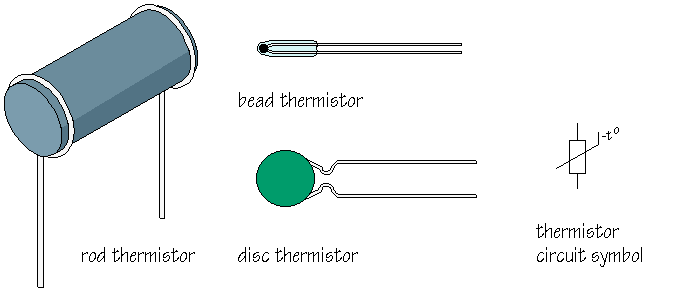

A Thermistor is a type of temperature-sensitive resistor whose electrical resistance changes significantly with temperature. It is commonly used in electronic devices and temperature control systems.

An Infrared (IR) thermometer measures temperature without direct contact with the object. It detects the infrared radiation emitted by the object, and converts it into a temperature reading.

IR thermometers are used for non-contact measurements, remote measurement, or in hazardous environments.